Evesham based British Made Shutters tasked the team at MPS to find a solution to spray their made to measure shutters. They had been pain stakingly looking for an automated solution to spray their parts faster and more efficiently to enable them to continue with expansion and growth.

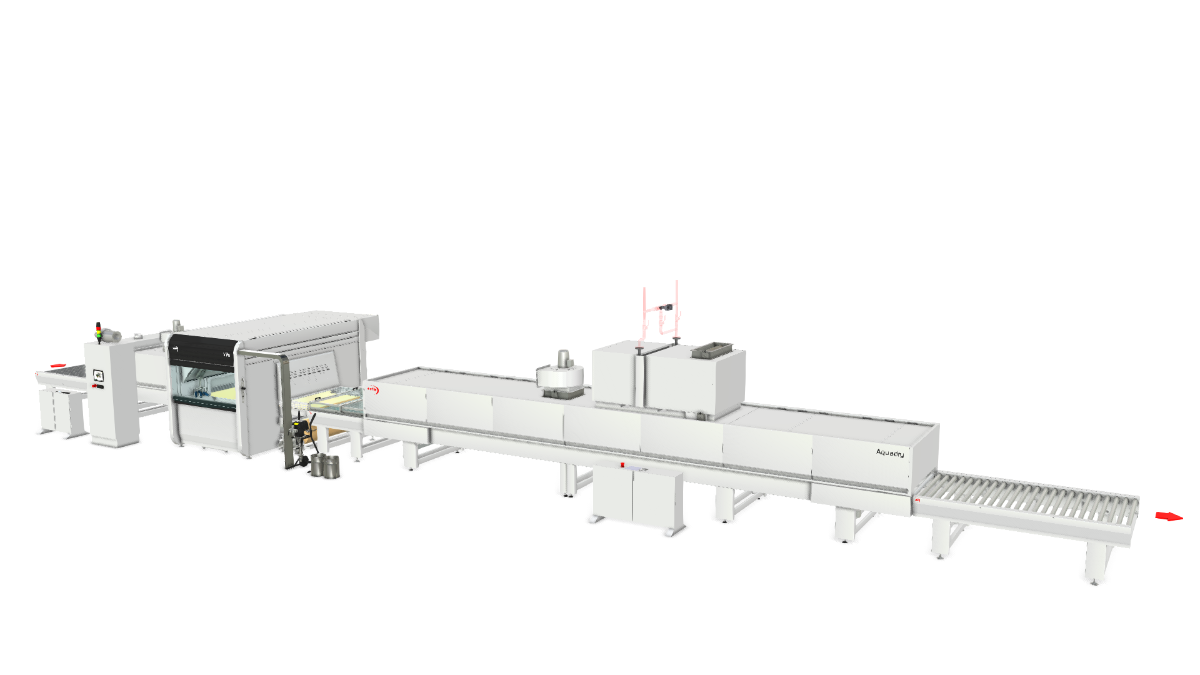

After successful investigations along with final trials at the Cefla lab, plus visits to many UK customers, an order was placed for a line consisting of infeed conveyor with pre cleaning unit, a CEFLA Mito 2 arm reciprocating machine with outfeed, connected to an Aqua-dry tunnel, suitable for both solvent or water based paints.

The process is as follows:

Parts are cleaned, then sprayed, and passed through the Aqua-dry tunnel simultaneously, where the parts are unloaded “dry to dust” so there is no fear of the finished parts being contaminated by particles in the factory atmosphere.

The MITO is a single or double arm reciprocating spray machine, suitable for the application of any type of water or solvent-based paint or glue.

It is ideal for small to medium sized businesses that are looking for flexibility and productivity as well as cost-effective use.

The MITO is one of CEFLA`s most popular machines with successful installations throughout the UK

The CEFLA Aquadry is an in-line system for drying mainly water based paints. This combined in-line system associates the effectiveness of high speed hot air and high radiation capacity IR lamps. It is the most efficient system for drying water-based paints, because it cuts the times needed to evaporate any water contained in the finishes.

The hot air ventilation creates a high flow-rate area. The optional infra-red lamps can have differential wavelengths and penetration depths.