Description

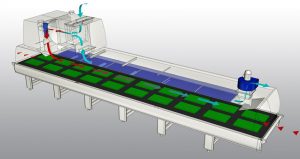

The solvents generated during spraying and flash-off are exhausted by means of a water curtain or dry spray booth, or special exhaust fans.

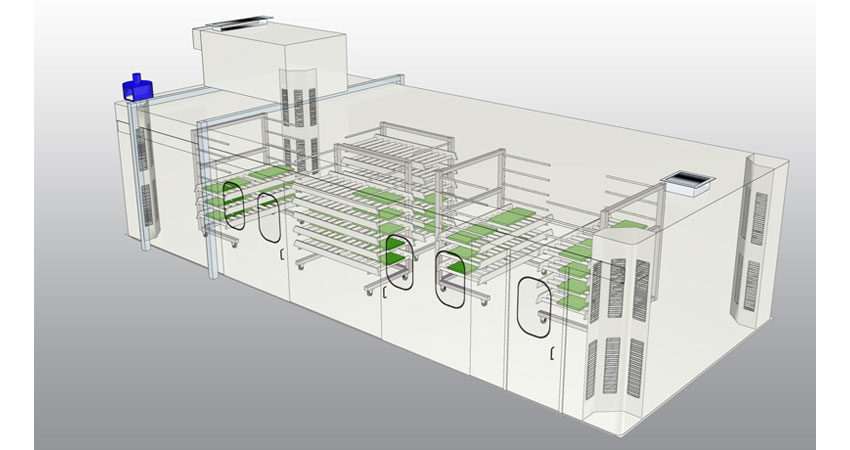

Pressurised booths and rooms

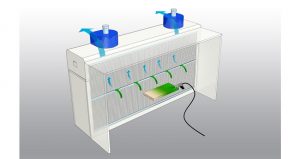

The creation of enclosed, pressurised rooms for spraying and/or drying coatings is essential in order to obtain end products of the highest quality and create an optimal work environment for operators. The uniform ventilation provided by external air make-up units keeps the air inside the booth completely free from dust from outside, eliminating all risk of contamination of sprayed workpieces. Air is delivered and filtered by air make-up units outside the booth or room.

The temperature and humidity level inside the room can also be controlled. The centralised control panel enables full control of all the plant functions: independent on/off switching for spraying room and/or drying room; independent temperature control for each room; drying cycle which can be programmed at end of shift; capability for maintaining minimal pressurisation even when not in use, to keep the inside environment dust-free; complete with energy-saving device.

Features

- The highest quality environment for outstanding finishing

- Controlled temperature and humidity levels

- The control panel allows full control of all the plant functions The uniform ventilation inside the booth keeps the air completely free from dust from outside, eliminating all risk of contamination of sprayed workpieces.

Materials:

- All