Ashley Ann are a highly successful family run business founded over 30 years ago, and they are a premier manufacturer of high quality Kitchens and bedrooms. Their state of the art manufacturing facility based in Northern Scotland has 160 employees supplying 8 of their own retail showrooms and many independent retailers across the UK.

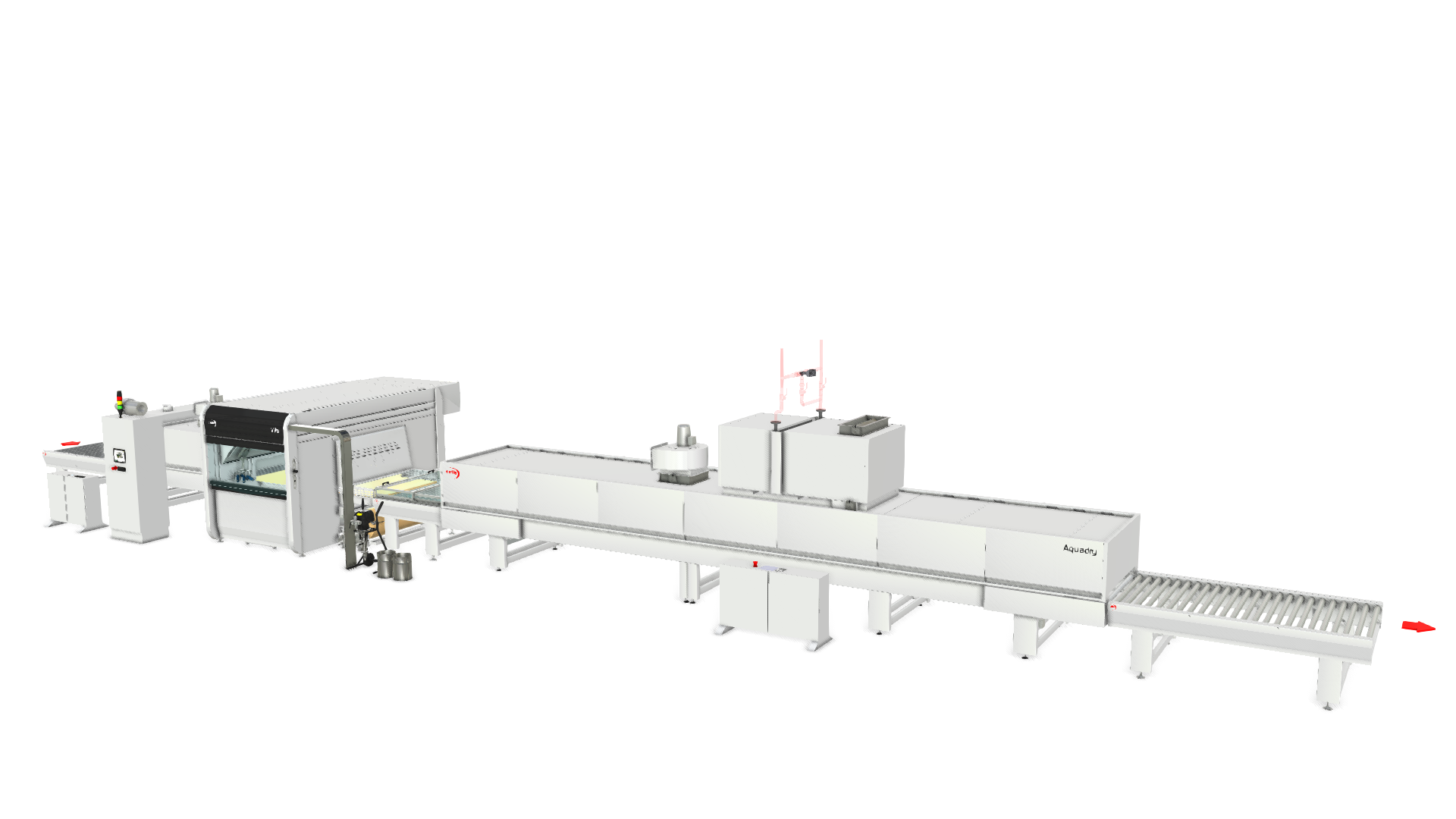

MD, Stephen Bremner, and his production team are constantly looking for ways to improve their manufacturing and quality, and identified their finishing process as an area that required further investment and improvement. Currently their products are sprayed manually and Stephen wanted to investigate a more automated solution to provide consistent high quality finishing with improved throughput and material savings. After successful investigations and visit to happy Cefla customers in the UK, an order has been placed for a line consisting of an infeed conveyor with pre-heating unit, A CEFLA Mito 2 arm reciprocating machine, with outfeed connected to an Aquadry tunnel for solvent and water based paints. The process will be as follows: The parts are cleaned, sprayed, then passed through the Aquadry tunnel simultaneously, where the parts are unloaded “dry to dust” so there is no fear of the parts being contaminated by partials in the atmosphere

CEFLA MITO and Aquadry line for Ashley Ann Kitchens and Bedrooms

The MITO has a reading bar at the infeed which scans the dimensions of the pieces and is relayed to the control software which allows the spraying to be optimised, minimising paint wastage. The MITO can be equipped with 1 central or 2 side arms, with 4 or 8 guns. The arms are able to manage colour/product change automatically and fast. Valve and time control can be handled directly by the software. The MITO has a patented “Airsphere” Plenum to guarantee a flow of perfectly clean air into the spraying zone, eliminating overspray residues during processing. The system ensures a high quality finish. Overspray is extracted through two-stage dry filters: the operating maintenance costs of this system are reduced to a minimum. The large filtering surface area guarantees better air distribution, which translates into uniform finishing and a cleaner machine.

CEFLA Aquadry In- Line drying oven

The CEFLA Aquadry is an in-line system for drying mainly water-based paints. This in-line system combines the effectiveness of high speed hot air and high radiation capacity IR lamps. It is the most efficient system for drying water-based paints, by reducing the time needed to evaporate any water contained in the finishes. The hot air ventilation creates a high flow-rate area. The optional infra-red lamps can have differential wavelengths and penetration depths

The Ashley Ann line is the perfect solution for bespoke manufacturers wanting to use water based paints with excellent drying results, small batch production with fast colour change, consistent high quality finishing with over 20% material saving and improved output – to find out more about how CEFLA finishing solutions can help your business contact us today!