Flawless intermediate sanding after priming is key to archive the perfect final lacqure finish. Unfortunately, this step in the sanding process generates large amounts of fine sanding dust. These fine dust particles are slimier in size to the sanding marks and remain tightly wedged in these grooves so require a great deal of effort to efficiently remove them from the surface.

As a rule, sanding machines are equipped at the out-feed with various dust extraction methods such as compressed air jets or vacuum devises that can prove ineffective. Following this cleaning process, however, large quantities of fine dust still remain firmly attached to the surface. Wiping the supposedly clean surfaces with a microfibre cloth finds evidence of residual fine dust. Even brush cleaning applications frequently fall short when confronted with the large amounts of fine dust created. Brushes are literally suffocated with fine dust accumulating on the surfaces of the filaments and clogging up the brushes. As any person who has ever tried to sweep snow with a broom will be well aware, after a very short time, the spaces between the bristles fill with snow and the broom slides over the snow instead of sweeping it up.

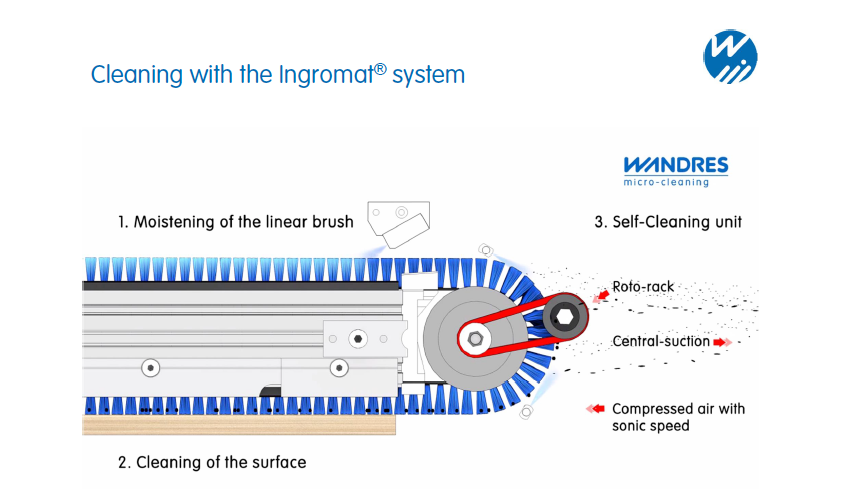

A modular cleaning unit combing ventilation technology and brush cleaning has passed the test with flying colours in continuos industrial panel production. A

process combining Tornado Channel and Sword Brush can significantly reduce reject rates arising from inclusions of particles in the lacquer coat. As a result, finer coats can be applied which has a positive effect on the quality of the surface finish, in particular regarding surfaces with a mirrorlike high gloss finish.

As a favourable knock-on effect, the amount of coating product required is minimized thereby lowering production costs, machine downtime is cut and concentrations of fine particulate matter in the production area reduced,

thereby improving workplace health and safety standards. The combination of

Tornado Channel and Sword Brush delivers cutting-edge cleaning technology for the cost-efficient and replicable mass production of high gloss furniture panels with a superior surface finish.